Servo controlled piston pump filling Machine

Brightwin liquid Filling machine

Overview of Brightwin liquid filling machine

This machine is used to fill various liquid, viscous liquid or thick liquid products, like cooking oil, lube oil, beverage, juice, sauce, paste, cream, honey, shampoo, detergent, pesticides, and Liquid fertilizer etc as long as it can flow. It adopts piston pump filling with servo motor driven which is more accurate and easy to adjust the volume. With rotary valve for thick or viscous liquid products and non-rotary valve for liquid products.

Agricultural chemicals/pesticide liquid

Daily use chemical liquid

Food & Drink liquid

Industrial chemical liquid

Pharmaceutical liquid

Features of Brightwin liquid filling machine

1. With PLC + human-computer touch screen control system. The PLC can save the parameters for later use. Operators do not need too much complicated operation.

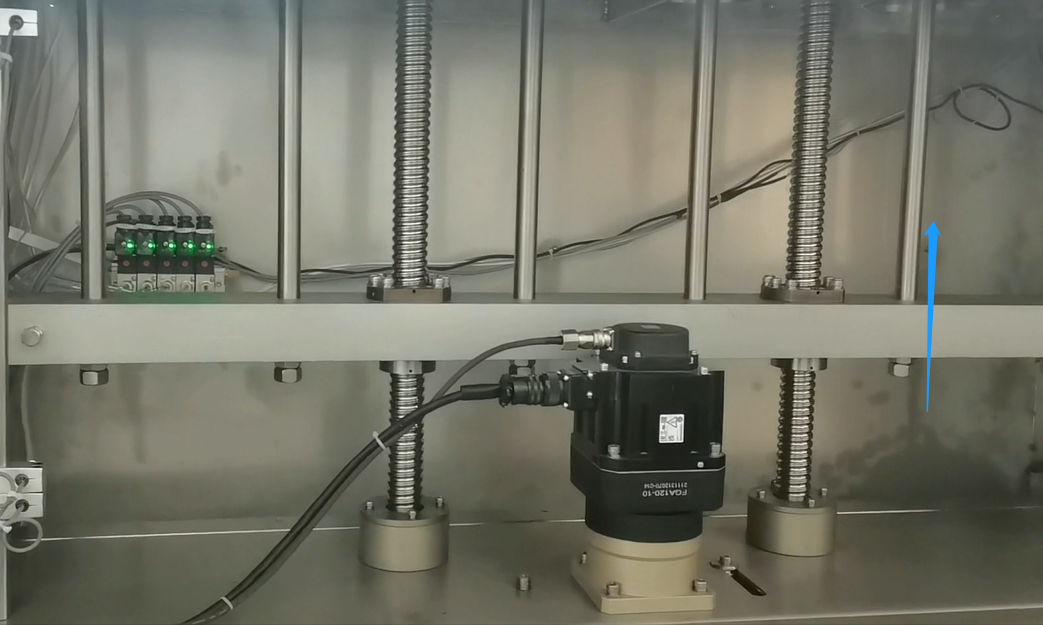

2. Adopts Mitsubishi servo motor to drive piston pumps, with high speed and high filling accuracy; its also easier for adjusting volumes, only need to input the volume you want to fill from touch screen.

3. The filling nozzles can be with the function of anti-drip, anti-drawing, diving bottom up filling, & bubble-kill etc according to the features of different products.

4. For hot filling, we make double jacket tank, which can be heated to keep temperature of products inside. Also with a mixer inside to stir it even.

5. There is a level controller in tank to control the pump to transfer product to the machine tank or stop transferring automatically.

Elements brand of Brightwin liquid filling machine

|

Item |

Brands and material |

|

sensor |

Omron |

|

PLC |

SIEMENS/Mitsubishi |

|

Touch screen |

SIEMENS/Mitsubishi |

|

Servo motor |

Mitsubishi |

|

Piston cylinder |

5MM thick SUS316L |

|

Rotary valve |

SUS316L |

|

Rotary valve connection |

quick coupler designed from Germany |

|

Filling nozzles |

SUS316L stainless steel anti-drip quick-coupler design |

|

Cylinder |

Airtac Taiwan |

|

Connecting pipe |

fast loading pipe from Italy |

|

Sealing ring |

food grade material from Germany |

|

electrical parts |

Schneider |

|

Rack |

SUS304 |

|

bearings |

Japan NSK, original imported |

|

Level control in hopper |

with |

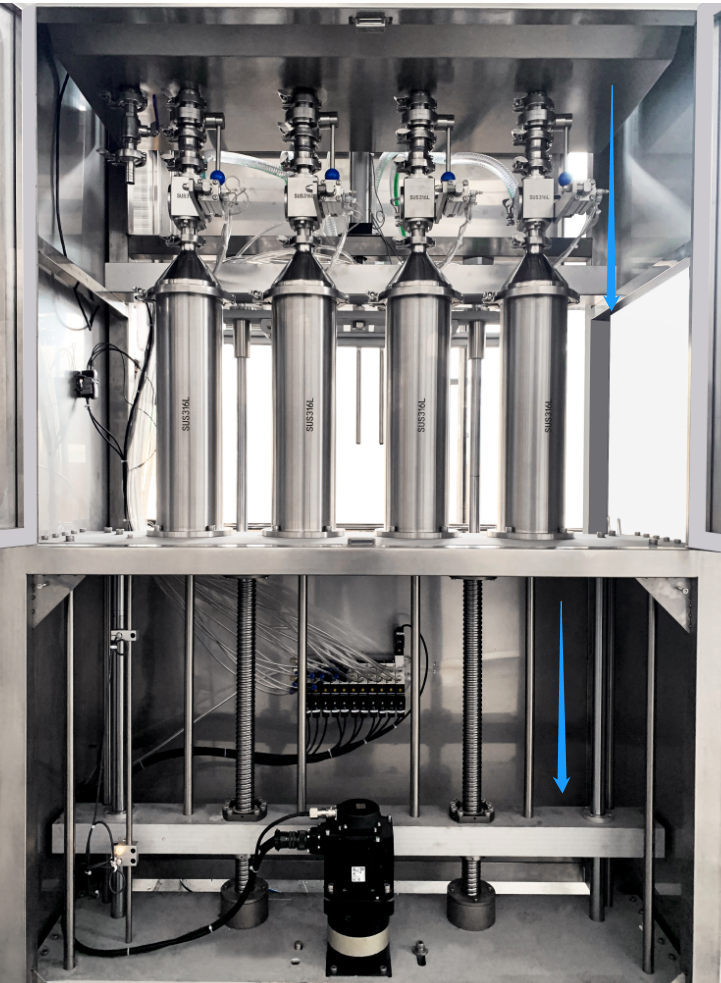

Working steps of Brightwin liquid filling machine

step 1: liquid is pumped through the pipe into the hopper of the liquid filling machine

step 2: servo motor rotate to move the piston down suck the liquid from hopper into piston

step 3: conveyor moves, brings the empty bottles.

step 4: When enough bottles arrive at the filling positions, bottles will be stopt

step 5: filling nozzles come down dive into bottle mouths, servo motor rotate to move the piston up push the liquid out from the piston pump, at the same time filling nozzle open, liquid flows through the pipes and filling nozzles finally be filled into bottles

step 6: bottles filled with requested volume liquid, filling nozzles lift up and filled bottles will be let go.

Parameters of Brightwin liquid filling machine

|

program |

filling machine |

|

Filling head |

2, 4, 6, 8, 10, 12, 16 etc(optional according to speed) |

|

Filling volume |

1-5000ml etc(customized) |

|

Filling speed |

200-6000bph |

|

Filling precision |

≤±1% |

|

Power supply |

110V/220V/380V/450V etc(customized) 50/60HZ |

|

Power supply |

≤1.5kw |

|

Air pressure |

0.6-0.8MPa |

|

Net weight |

450kg |

Special advantages of Brightwin liquid filling machine

1. SUS 316 piston composes with Sealing ring imported from Germany, which is no need to replace within 3 years.

2. Sepcially designed SUS316L LONG no–drip filing nozzles, which can protect the cylinder on the top being damaged by material.

3. 304 frame, 5mm thick SUS316L honing piston pump, manufactured by Taiwan producer.

4. With detector in each SUS316L valve, if there is any problem in any nozzle, it shows in touch screen, its easy to be found.

5. other details

After sales service of Brightwin liquid filling machine

1. Offer professional operation manual

2. Online support

3. Video technical support

4. Free spare parts during warranty period

5. Field installation, commissioning and training

6. Field maintenance and repair service