New Fashion Design for Vial Filling And Sealing Machine - Brightwin wash solution buffer filling line for a customer from Saudi Arabia – Brightwin

New Fashion Design for Vial Filling And Sealing Machine - Brightwin wash solution buffer filling line for a customer from Saudi Arabia – Brightwin Detail:

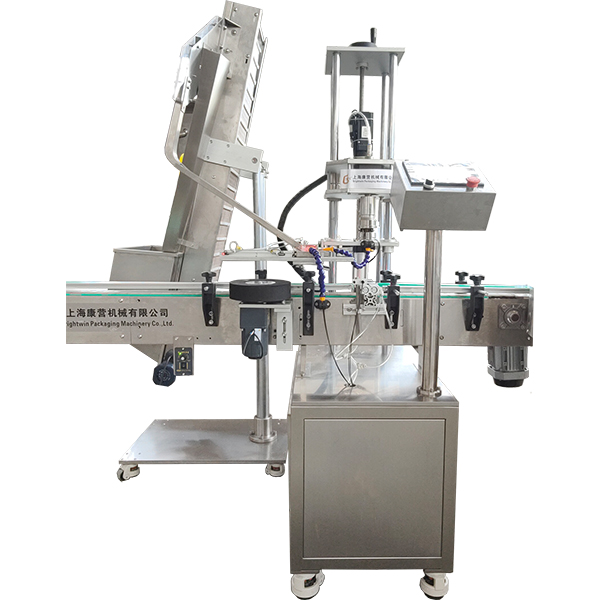

Washe solution buffer servo filling elevator feeding caps servo screw capping machine line. The whole line was assembled bottle feeding turntable and collection turntable to be an automatic packaging line.

Workers place empty bottles on the turntable, through the rotating of the table, bottles will rotate with it, guide bar will guide bottles to the outlet track one by one.

The line is adjustable for many different shape and size containers. This 4 nozzles servo filling machine fills 4 bottles at the same time, also can be used as any other automatic liquid filling machine, like oil filling machine, etc.

Since customer’s bottle have same caps, we used vibrator to feed caps to save customer’s cost. Capping head is movable, when a cap is ready, capping head goes catch it, and back to origin position to wait for filled bottles, once a bottle arrives, capping head down and screw the cap tightly on the bottle mouth.

Finished bottles come with conveyor, will be collected in this turntable, waiting for workers to do next packaging movement.

| Program | Liquid filling machine |

| Filling nozzle number | 4 |

| Capacity for 30ml bottles | 30bpm |

| Capacity for 125ml bottles | 30bpm |

| Accuracy | ≤±1% |

| Air pressure | 0.6-0.8MPa |

| Voltage | 220V Single phase |

| Power | 3KW |

The line is ready to go, waiting for customer’s arrangement!

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for New Fashion Design for Vial Filling And Sealing Machine - Brightwin wash solution buffer filling line for a customer from Saudi Arabia – Brightwin , The product will supply to all over the world, such as: Swansea, San Francisco, New Zealand, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.