Wash free hand washing gel 4 nozzlesfilling spindle capping double sides and round bottle labeling machine line for an Algeria customer

This customer had 5 size products: 100ml, 0.5L, 0.8L, 1.5L, 5L, different size and different shape bottles. The whole line was adjustable, and it was an automatic line from A to Z.

Workers can pour many bottles on the table, then arrange and place empty bottles by hand one by one on the conveyor of the table, when conveyor rotating, bottles will go with it.

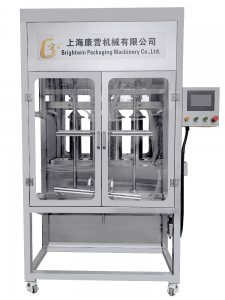

The line is adjustable for many different shape and size containers. This 4 nozzles servo filling machine fills 4 bottles at the same time, also can be used as any other automatic liquid filling machine, like oil filling machine, etc.

The spindle capping machine can adopt elevator or vibrator to feed caps. Elevator has large adjust range, different size caps just need to change the cap tracks. But some special caps just can be arranged by vibrator, cause the shape or size or other features.

This machine is an automatic machine, can finish caps placing and tightening them on bottle mouth automatically.

Customer has both round bottle and rectangle bottles, we adopted munti-function labeling machine which can label both round bottles and rectangle bottles automtacitally, no need to change parts, just need to adjust the machine according to different size and different shape bottles. Customer can adjust it according to the bottles they are filling and capping.

| Program | Liquid/thick liquid filling machine |

| Filling nozzle number | 4 |

| Capacity for 5000ml bottles | 10-15bpm |

| Capacity for 100ml bottles | 30bpm |

| Accuracy | ≤±1% |

| Air pressure | 0.6-0.8MPa |

| Voltage | 220V Single phase |

| Power | 6KW |

This customer loves our machines very much, he ordered this line on 2020, and now he is paying for the other line.