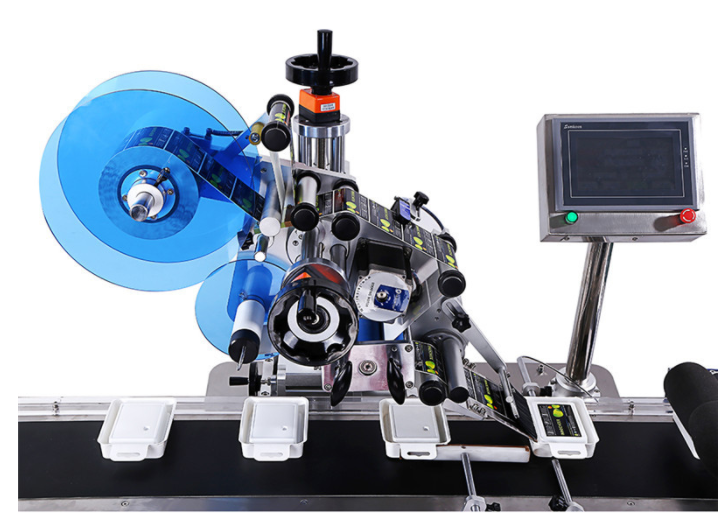

Horizontal Labeling Machine

Horizontal Sticker labeling machine is widely used for such industries as food, medicine, fine chemical, cultural supplies, and electronics and so on.

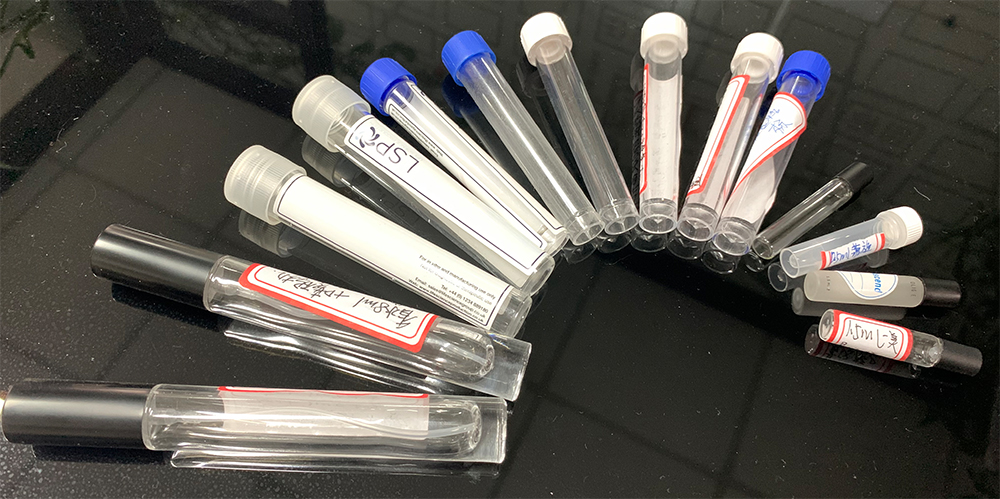

It is applicable for the labeling of the objects with small diameters and unable to stand up easily, such as oral liquid bottles, ampoule bottles, needle tube bottles, batters, hams sausages, test tubes, pens and so on. And it is also applicable for the flat top labeling of boxes, carton cases or some special shape containers.

Circle labeling for round objects:

like tubes, small round bottles, etc, which are difficult to be labeled while standing.

Flat labeling for bottles or boxes:

top of bottles, boxes, cartons, or other object.

|

Model |

BW-WS |

|

Drive |

Step Motor Driven |

|

Labeling Speed |

100-300pcs/min |

|

Bottle Diameter |

8-50 mm |

|

Bottle Height |

20-130mm |

|

Label Size |

Width: 10-90mm Length: 15-100mm |

|

Precision |

±1mm |

|

Label Roll |

Max: 300mm |

|

Label Core |

Stander: 75mm |

|

Machine Size |

1600*600*1400mm |

|

Weight |

220Kg |

|

Power |

AC 110/220v 50/60Hz 500W |

➢ Principle: After separating system the bottles, sensor detects it and give signal to PLC, the PLC will order motor to put the labels on the suitable position on the labeling head to label the bottles when bottles pass.

➢ High accuracy. With deviation correcting device for labeling to avoid label deviating. Stable performance, excellent labeling result without wrinkles and bubbles.

➢ Stepless motor for speed adjusting on labeling conveyor, bottle separating.

➢ No bottles no labeling, self-inspection and self-correction for no labels situation

➢ Durable,adjusting by 3 poles , taking advantage of stability from triangle. Made or stainless steel and high quality aluminum, conforming to GMP standard.

➢ Original design for mechanical adjusting structure and labeling rolling. The fine adjusting for freedom of motion in label position is convenient( can be fixed after adjusting), making easy the adjustment and winding labels for different products

➢ PLC+ touch screen + stepless motor + sensor, save working and control. English and Chinese version on touch screen, error reminding function. With detailed operation instruction including structure, principles, operations, maintenance and etc.

➢ Optional function: hot ink printing; automatic material supply/ collecting; adding labeling devices; circle position labeling, and etc.

1. Printing device

According to your printing details on labels, you can choose different printing device. The device will be installed on the labeling machine, it will print stickers before the machine labels them onto the objects.

Ribbon character printer for simple date(like: production date, shelf life, validity, etc.), number code, etc.

Heat transfer printer for QR code, bar code, etc.

2. Glass cover

Whether the glass cover needs to be added, up to you.