Automatic 1-25L lube oil engine oil motor oil bottle filling capping labeling machine

Liquid automatic filling machine

This machine is widely used in the filling of liquid and viscous liquid products in the food, medicine, chemical, daily chemical, oil, fishery, pesticide and other industries. The parts in contact with materials are made of high-quality stainless steel, which conforms to GMP standards.

Performance characteristics:

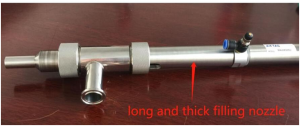

1.This machine adopts a special three-way filling valve with compact and reasonable design, simple and beautiful appearance;

2.The motor is used to adjust the cylinder stroke, and the filling volume is easy to adjust;

3.Automatic bottle feeding, filling and bottle discharging, no filling if there is no bottle;

4.The filling volume is accurate and has a counting function;

5.Using PLC programmable control, equipped with a 6-inch touch screen human-machine interface system;

6.All electrical components adopt international brands to ensure excellent quality and long-lasting stable performance;

7.Equipped with a filling head to prevent dripping and drawing, to ensure that there is no dripping after filling;

Equipped with a submerged filling system to ensure that there is no foam during the filling process and prevent the filling from overflowing.

Sanitary valve pipeline, quick connection, filling area covered with plexiglass, beautiful and dustproof.