An American customer’s cosmetic cream liquid 6 nozzles filling 2 nozzles capping horizontal labeling machine line

Container of the cosmetic liquid 6 nozzles filling 2 nozzles capping horizontal labeling machine line

Video of the cosmetic liquid 6 nozzles filling 2 nozzles capping horizontal labeling machine line

Apperance of cosmetic liquid 6 nozzles filling 2 nozzles capping horizontal labeling machine line :

Introduction cosmetic liquid 6 nozzles filling 2 nozzles capping horizontal labeling machine line :

Cosmetic liquid 6 nozzles filling 2 nozzles capping horizontal labeling machine line is ideal for bottle with spray head cap filling capping and labeling.

The machine can finish all the movement automatically without labor, just need workers to place bottles caps and stickers periodicitily. It has extremely high stability and productivity, which can save lost of labor costs and time costs as much as possiblcan. Many factories are replacing labor with mechanization as much as possible.

Principle of the cosmetic liquid 6 nozzles filling 2 nozzles capping horizontal labeling machine line :

Workers place empty bottles into bottles vibrator, the vibrators will feed bottles into starwheel, bottles will go with the starwheel will be filled under filling nozzles. At the same time workers place new caps into caps vibrator, the caps vibrator will feed caps in line to wait for capping. When filled bottles come, capping head will pouch the caps into filled bottles and tighten them. Finally, finished bottles will lie down to be labeled with whole circle of stickers on the bodies.

Working steps of the the cosmetic liquid 6 nozzles filling 2 nozzles capping horizontal labeling machine:

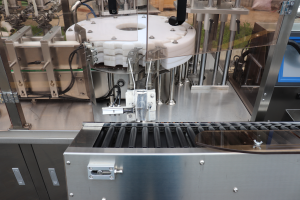

Step 1: Bottles vibrator feeding bottles

Step 2: Peristaltic pump filling empty bottles

Step 3: Caps vibrator feeding caps

Step 4: Mechnical arm take and put caps

Step 5: Capping heads pressing tighten the caps

Step 6: Filled and capped bottles lie down

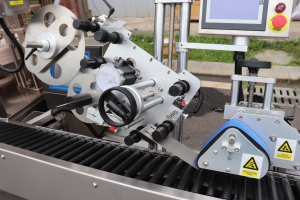

Step 7: Labeling head labeling the bottles

This machine is mainly applied to various material round bottle, flat bottles. Filling material could be small dose of liquid, like transfer tube,and eliquid etc peristaltic pump keep the filling liquid clean ,has high measuring precision.

The machine finished all works of bottle feeding, filling ,putting inner plug and capping outer covers automatically.

- High filling precision

- The machine adopts full-auto PLC and human-computer touch screen control system.

- No bottles, no filling.

- Magnetic moment capping, adjustable on pine, tight, do not hurt the jar and cover.

- Versatility, suitable for different specifications and bottle type, changing accessories convenient;

- Stepless speed regulation, the microcomputer, man-machine interface control, convenient operation adjustment

- Mechnical arm take and put cap, stable and very accurate

Parameter of the cosmetic liquid 6 nozzles filling 2 nozzles capping horizontal labeling machine line

| Program | Liquid filling machine |

| Filling nozzle number | 6 |

| Capacity for 7ml bottles | 70-80bpm |

| Capping head number | 2 |

| Accuracy | ≤±1% |

| Air pressure | 0.6-0.8MPa |

| Voltage | 220V Single phase |

| Power | 3KW |