OEM/ODM China Jar Capping Machine - Spindle Capping Machine – Brightwin

OEM/ODM China Jar Capping Machine - Spindle Capping Machine – Brightwin Detail:

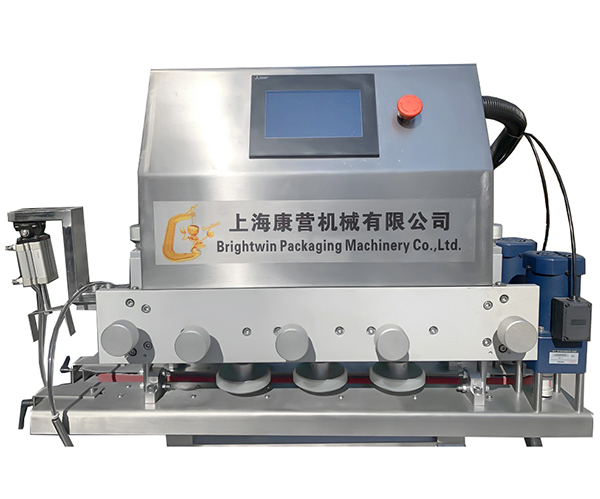

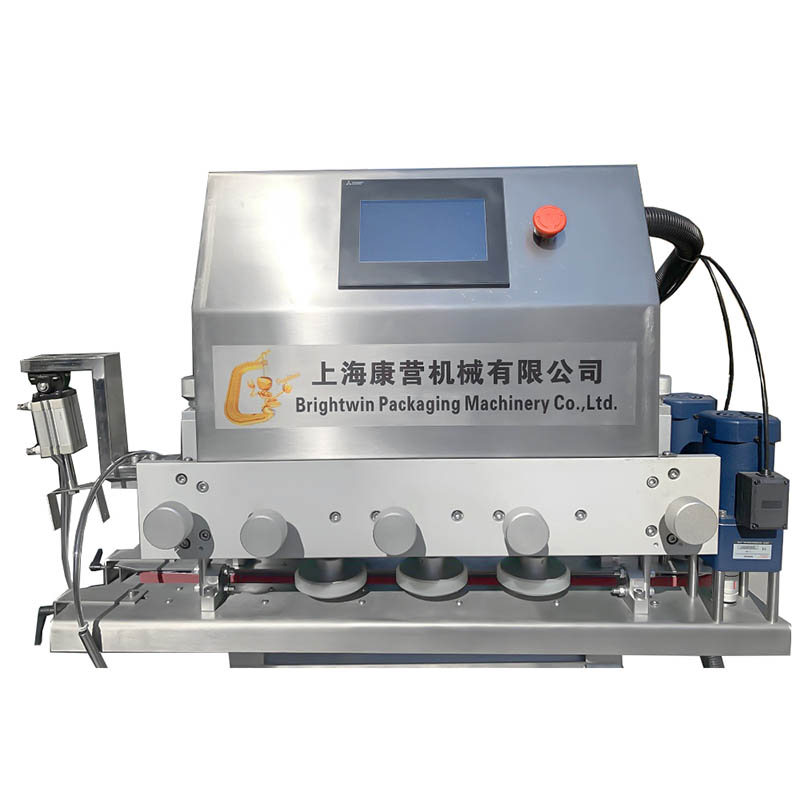

Spindle capping machine

● ‘one motor controls one capping wheel’, which can ensure the machine to work stably and keep consistent torque under long term working condition.

● Easy to operate.

● Mitsubishi PLC and touch screen control, easy to operate.

● The gripping belts can be adjusted separately to coordinate with different bottles.

● If equipped with guidance device, the machine can cap the pump caps.

● Rulers on every adjusting parts to make the adjustment “visible”.

● The torque limiter is optional to make sure the consistent torque.

● The up-down motor is optional to make the machine go up and down automatically.

● This machine is for the caps 10mm-100mm regardless the shapes as long as screw caps. This machine has the original design, easy to operate and adjust. The speed can reach 200bpm, freely used separately or combined into production line.

● When you use semi-automatic spindle capper, the worker only needs to put the caps onto bottles, during their moving forward, the 3 groups or capping wheels will tighten it.

● You can choose the cap feeder to make it fully automatic (ASP). We have the cap elevator, cap vibrator, declined plate and etc. for your choice.

Caps diameters: 10-100mm

Bottle diameters: 10-150mm

Bottle gripping speed: 0-17.4m/min

Spindle wheels speed: 0-18.5m/min

Productivity: 50-200bot/min

Power supply: 220V, single phase

Wheel torque: 10-70N*m

1. Offer professional operation manual

2. Online support

3. Video technical support

4. Free spare parts during warranty period

5. Field installation, commissioning and training

6. Field maintenance and repair service

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of OEM/ODM China Jar Capping Machine - Spindle Capping Machine – Brightwin , The product will supply to all over the world, such as: New Orleans, Frankfurt, Philadelphia, We expect to provide products and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.