Factory selling Liquid Filling Machine For Cosmetic Oil - Automatic bottle filling capping labeling machine – Brightwin

Factory selling Liquid Filling Machine For Cosmetic Oil - Automatic bottle filling capping labeling machine – Brightwin Detail:

This machine is used to fill various liquid or viscous liquid products, like cooking oil, lube oil, beverage, juice, sauce, paste, cream, honey, and chemicals etc as long as its liquid. It adopts piston pump filling with servo motor driven which is more accurate and easy to adjust the volume. With rotary valve or non-rotary valve according to different products.

Parameter

|

program |

filling machine |

|

Filling head |

2, 4, 6, 8, 10, 12, 16 etc(optional according to speed) |

|

Filling volume |

1-5000ml etc(customized) |

|

Filling speed |

200-6000bph |

|

Filling precision |

≤±1% |

|

Power supply |

110V/220V/380V/450V etc(customized) 50/60HZ |

|

Power supply |

≤1.5kw |

|

Air pressure |

0.6-0.8MPa |

|

Net weight |

450kg |

Elements brand

|

Item |

Brands and material |

|

sensor |

Omron |

|

PLC |

SIEMENS |

|

Touch screen |

SIEMENS |

|

Servo motor |

Mitsubishi |

|

Piston cylinder |

5MM thick SUS316L |

|

Rotary valve |

SUS316L |

|

Rotary valve connection |

quick coupler designed from Germany |

|

Filling nozzles |

SUS316L stainless steel anti-drip quick-coupler design |

|

Cylinder |

Airtac Taiwan |

|

Connecting pipe |

fast loading pipe from Italy |

|

Sealing ring |

food grade material from Germany |

|

electrical parts |

Schneider |

|

Rack |

SUS304 |

|

bearings |

Japan NSK, original imported |

|

Level control in hopper |

with |

Details of filling machine

1. The material of sealing ring is imported from Germany. It is composed of stainless steel spring and UPE (ultra high molecular weight polyethylene).

2. Equipped with SUS316L long sepcial designed no–drip filing nozzles, which can protect the cylinder on the top being damaged by material. As following pictures:

3. 304 frame, 5mm thick SUS316L honing piston pump, manufactured by Taiwan producer

4. With detector in each SUS316L valve and filling nozzle, if there is any problem in any nozzle, it shows in touch screen, its easy to be found.

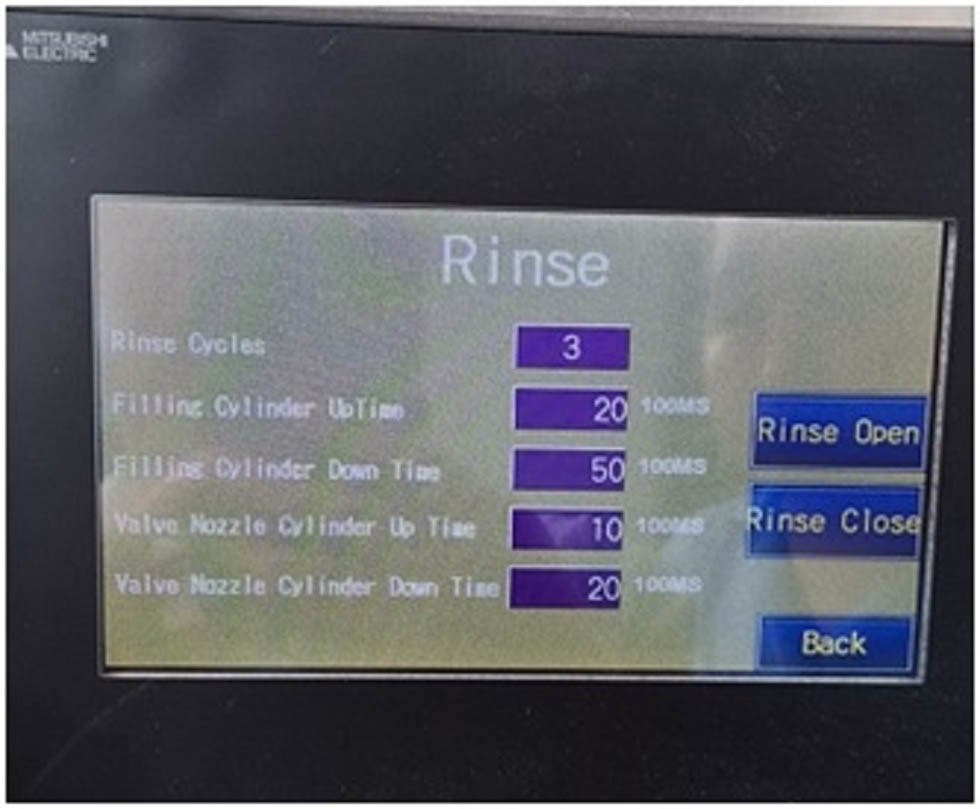

5. With automatic cleaning system

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Factory selling Liquid Filling Machine For Cosmetic Oil - Automatic bottle filling capping labeling machine – Brightwin , The product will supply to all over the world, such as: Georgia, Nigeria, Angola, In order to meet the increasing requirement of customers both home and aboard, we will keep carrying forward the enterprise spirit of "Quality, Creativity, Efficiency and Credit" and strive to top the current trend and lead fashion. We warmly welcome you to visit our company and make cooperation.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.